The resource-efficient production of chemicals, as well as the mitigation of harmful emissions, are largely enabled by heterogeneous catalysts. The large-scale production of catalysts, however, can be a challenge for companies and research institutes due to a lack of adequate production facilities, technological expertise and raw material supply chains.

Heraeus Precious Metals, as a leading catalyst producer, can manufacture your supported precious metal based catalysts under toll contracts. Profit from a partner with decades of experience in the development and upscaling of precious metal-based catalysts. Heraeus is well-equipped to scale-up your intellectual property (IP) from the bench scale to the level of a commercial product.

Outsourcing your company‘s catalyst production to an experienced catalyst production specialist cannot only help you to focus on your core competencies but can also improve your short- and long-term profitability

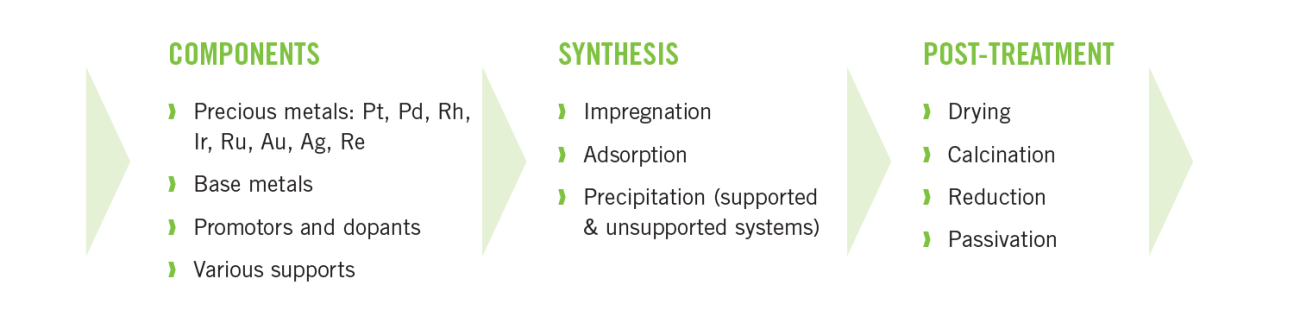

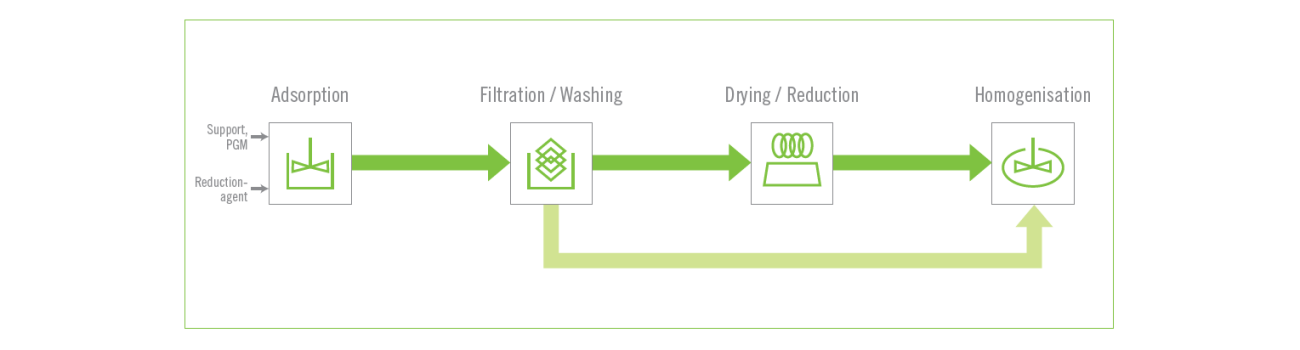

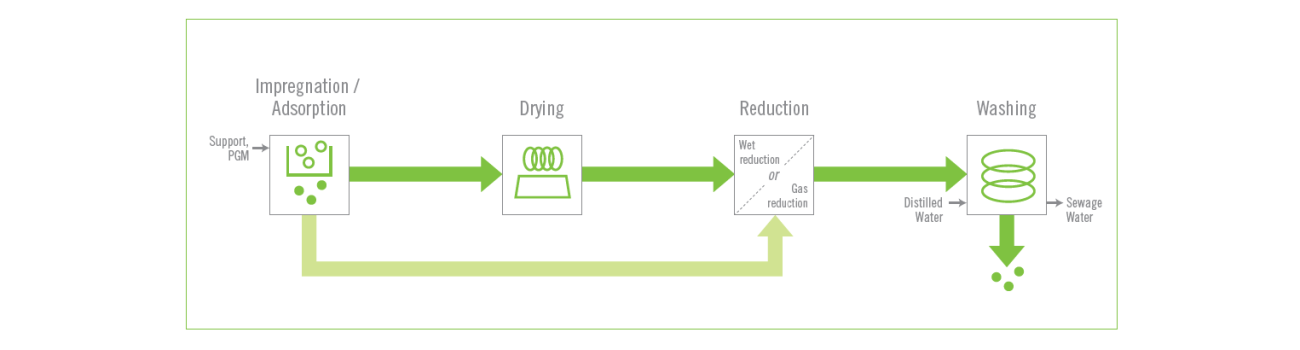

In general, production procedures can be adapted to your specific needs. If desired, the experts of Heraeus assist with the development of catalysts in joint catalyst development programs. By fostering a strong collaboration at all stages of development, testing and production, Heraeus guarantees high-quality catalyst products that are finetuned to your demands and applications.